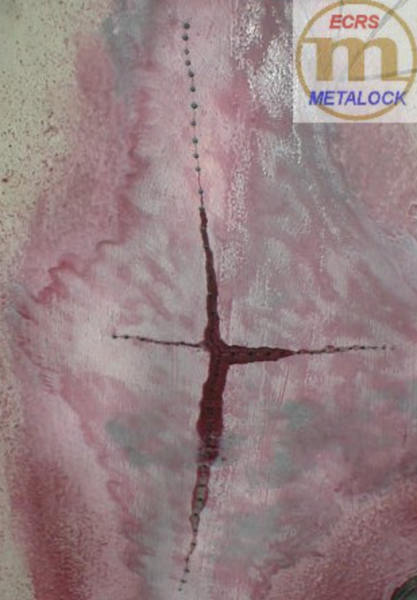

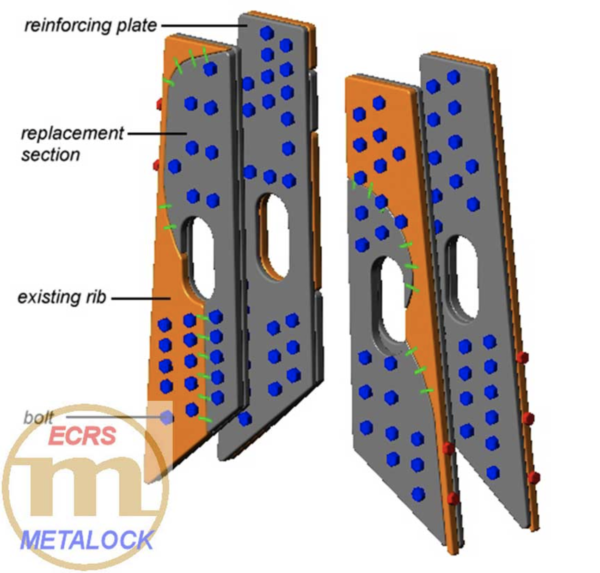

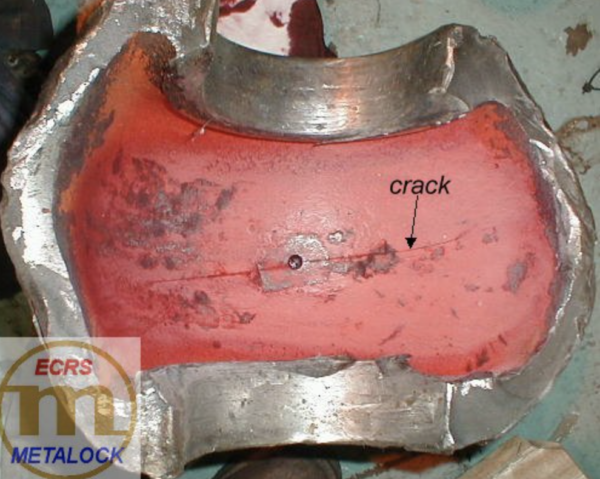

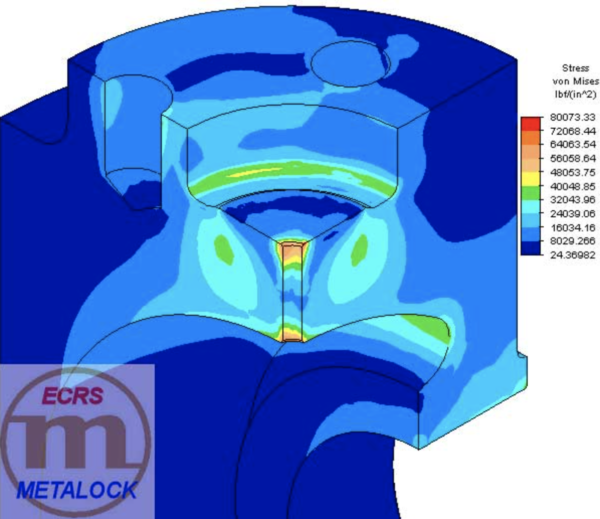

Profile drilling was also performed on all cracks in the upper frame to determine their depths and exact endpoints. The cracks in the upper frame and the fracture surfaces of the partitions were examined visually and with dye penetrant to determine the true extent of the cracking. Based on the results of these inspections, it was determined that “cracks” would be repaired by the installation of Metalock and Metalace repair components along their entire length. As part of the repair process, the fracture surfaces of the damaged ribs were modified to a more suitable geometry for the installation of the steel replacement sections. been modified to receive the new sections, templates of the cavities were used to manufacture new replacement sections from one inch thick steel plate. Additional reinforcement of the vertical support ribs was in the form of three quarter inch steel plates manufactured to the same profile as the original ribs. The replacement sections were attached to these reinforcing plates with a series of high strength bolts before their attachment to the frame. The next step in the repair procedure was to install the upper and lower rings for the slide guide. Then all nuts on the replacement ribs were tack welded to the steel plates as well as to the bolts to assure that the repair would never loosen.

Want to See More Case Studies?

Contact Us

Interested in learning more about our machinery repair or other services? Simply fill out the form below and a representative will be in touch.Prefer to Speak with Someone Now?