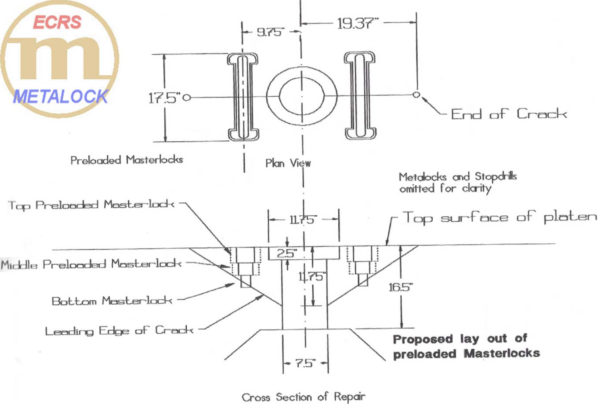

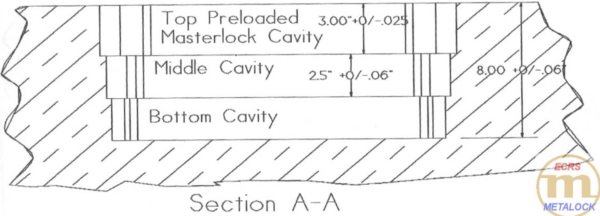

A forge facility in Haifa, Israel had a damaged 5,600 ton screw press platen. The four column screw press had cracking around the 7.5” diameter ejection hole. The cracks were approximately 15 5/8” along the platen surface and 11 ¾” down the bore. The proposed repair consisted of three Preloaded Masterlocks on either side of the ejection hole. The Preloaded Masterlocks were installed one on top of the other to create a deeper repair component ligament. Afterwards, the crack received additional Metalocks and Metalacing along with drill studs at the end of the cracks to deter further propagation. In addition to the repair components a 3 inch thick plate was installed onto the surface of the platen to reinforce the entire platen.

Want to See More Case Studies?

Contact Us

Interested in learning more about our machinery repair or other services? Simply fill out the form below and a representative will be in touch.Prefer to Speak with Someone Now?