Metalock and Metalace

The installation of these components will also seal and hold pressure. The major advantage of this process is the fact that these repairs eliminate or upset stress concentration in the parent material; therefore, improving the fatigue resistance of the part.

Preloaded Masterlock

Masterlock, our third process, is installed at points of stress or wear for maximum strength and efficiency. This device is used for a greater concentration of lock strength, a wide distribution of working stress, and the elimination of localized stress.

Mini-Keylock

One of our newer processes, the preloaded Mini-Keylock, can handle both large and small scale repairs that may fall between the smaller Metalocks and the much larger Masterlocks. These also work well in conjunction with repairs that utilize either Masterlocks or Metalocks as reinforcement components.

Conventional Masterlock

Unlike the Masterlocks and the Mini-Keylocks the Conventional Masterlocks are not preloaded during installation. They are used when the work are may not accommodate the larger Masterlocks, but call for larger components than the Mini-Keylocks. The Conventional Masterlocks can also be used to deepen the ligament of the mechanical repair component by being installed under the larger Masterlocks and Anglelocks.

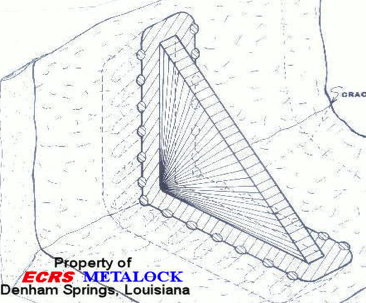

Anglelock

The Anglelock is implemented on cracks occurring along angled surfaces. These components are much like the Conventional Masterlocks in installation, and are not preloaded when in place. Because of this they are replaceable my ECRS/Metalock personnel when they have reached their maximum operational lifespan.

Welding

ECRS/Metalock is capable of addressing almost any welding needs for repairs. We are up to date and adhere to standards set by the American Welding Society and can provide a myriad of pre-heat and post-heat treating procedures to ensure a quality weld to the parent material.